Preparation and Material For the Perfect Diamond

One of the most important parts to polish a diamond is the polishing wheel. More specifically: a well-prepared polishing wheel. Nowadays there are various ready-to-use preparations to lubricate the wheel. This is often a mix of diamond powder, oil and a volatile liquid. Thanks to the latter, the mix is easy to apply and the powder remains. But in this blog, I explain how the disc is prepared in the traditional way: with olive oil and diamond powder.

Preparation materials

To polish a diamond well prepared, a few parts are needed. These parts are: the polishing wheel, diamond powder or “board”, olive oil and a pumice stone.

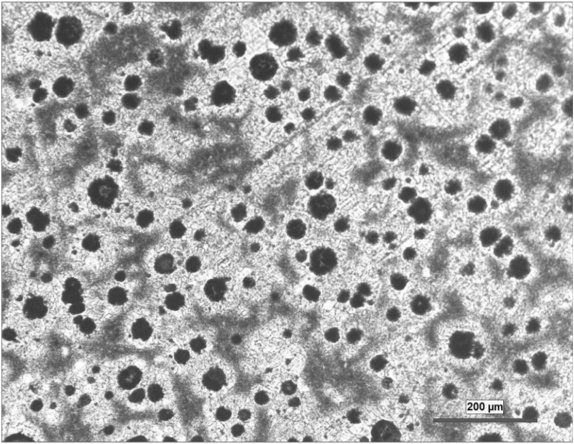

The wheel

The polishing wheel is a horizontal round disc on a spindle, made of cast iron. Cast iron is hard and inflexible. But it is also a bit porous. It is just its porous nature that makes cast iron so suitable for polishing. But we will come back to that later.

Diamond powder or board

Diamond powder is actually nothing more than pulverized diamond. In popular parlance, diamond powder is also called board. The gradations of the powder range from coarse to very fine. Which one we choose depends on the purpose. For example, we use very coarse powder to cut a diamond. Polishing the cross is best with coarse powder. But the brilliance polish requires fine powder.

Olive oil

We use oil to lubricate the cast-iron disc. Olive oil is preferred because it does not emit any odors when heated and has little to no pungent odor anyway. The thickness and spreadability are also important. My favorite is vergine. This is a bit thicker and easier to spread over the disc.

Pumice stone

Pumice is a very porous volcanic rock. Some pedicures use a pumice stone to scrape away excess (hard) skin such as calluses. I use the stone to make the just sanded discs flatter and nice and smooth. Thus the disc loses the worst roughness and becomes smoother.

Preparation of the wheel

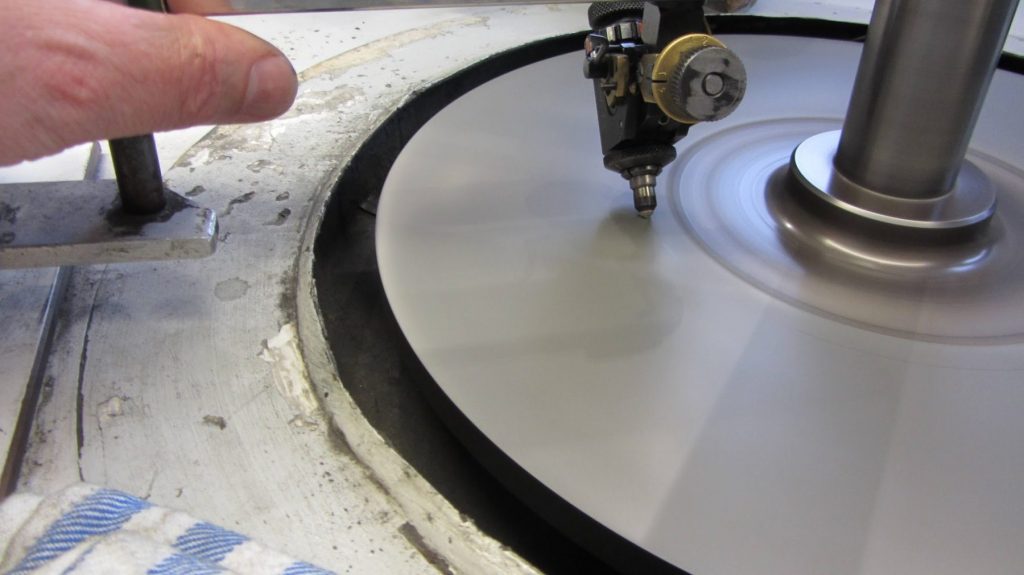

When the polishing wheel is delivered, it has just been sanded and is, therefore, rough. In order to properly prepare the disc for the polishing work, we must prepare it properly. The disc is clamped between two pieces of lignum vitae and we make sure it is properly leveled. The level is important because it ensures that the diamond in the pliers is cut the same in different positions.

When the disc is leveled and secure, we gently rub the pumice stone over the disc while it spins gently. This makes the scratches in the disc less deep. Then the disc is cleaned and degreased with ammonia and methylated spirits. This ensures a spotless surface to start with.

Applying the oil

We apply the olive oil by finger. Dip the finger in the oil and tap the disc every 5 centimeters.

Apply diamond powder

We distribute the diamond powder over the entire surface of the polishing wheel. Converted to carats, this is approximately 1 carat of diamond that has been pulverized.

Mix oil and powder

The oil and diamond powder are mixed on the disc by rubbing them in small circles at the same time. It is important that there is not too much oil on the disc. An excess of oil can give a bad polishing result. The good combination between powder and oil feels like a thick dry paste. The mixture dries well by rubbing it on the polishing wheel.

Settling of the polishing wheel

After the disk is prepared, it must be “settled”. This means that we will work the powder and the olive oil with a diamond in the tongs. As you may understand, we don’t do this with a diamond that only needs the tiny and precise brilliant facets. We prefer a diamond that we are “cross-cutting”. The facets are a lot larger and can therefore, be polished longer and more.

Usage of the polishing wheel

When the disk is all settled, it is ready to use. For polishing, the wheel is divided into two parts. We call the first part the “test circle”. That is the inner part of the disc. This spins (relatively) slower than the outside of the disc. The test circle owes its name to its function: we use this part to test where the facet of the diamond will be. The outer edge has no nickname, but it rotates faster than the inner circle and is therefore better to polish the diamond.

The polishing wheel rotates at a speed of 3000 to 3800 rotations per minute. This is the perfect speed. When the drive slows down, nothing happens. But if the disc spins faster, the disc burns the diamond, which can make it ugly.

The real polishing

When the disc has been settled properly, the real diamond polishing can begin. First, we test the stone in the top ring. Then we can see where the facet is and whether it is all going well. Then we can continue to polish on the outer ring and transform the rough stone into a beautiful cut diamond.